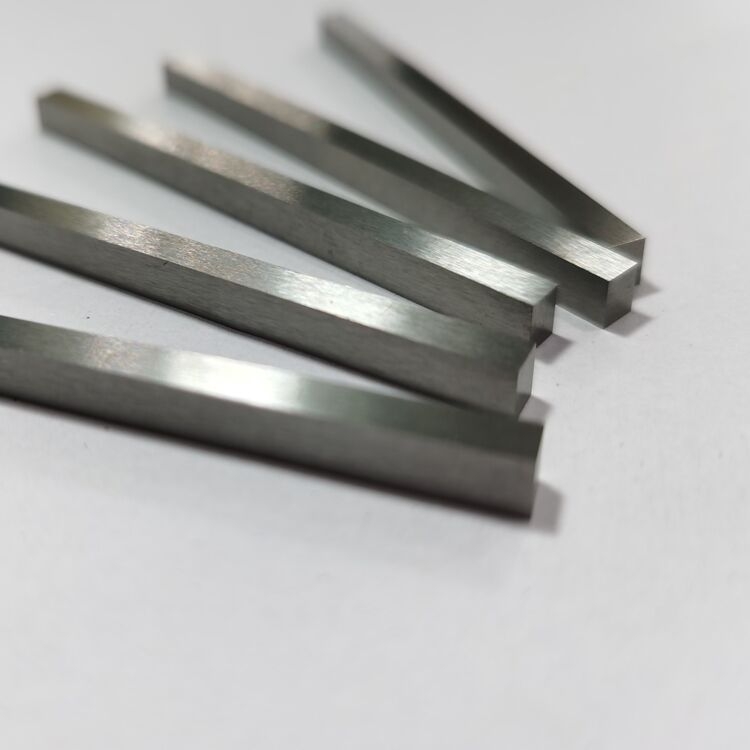

Igikoresho cy’ubutare gikozwe mu cyuma gikomeye gikozwe mu cyuma gifata icyuma n’icyuma gifata icyuma binyuze mu buryo bw’ifu. Carbide ikozwe muri sima ifite imiterere myiza nko gukomera cyane, kudashira, gukomera no gukomera, kudashira ubushyuhe no kudashira, cyane cyane gukomera kwayo no kudashira, bigumaho nubwo haba hari ubushyuhe bwa dogere selisiyusi 500, iracyafite gukomera cyane kuri dogere selisiyusi 1000. Carbide ikoreshwa cyane nk'ibikoresho by'ibikoresho, nko guhindukira, gukata ibyuma, planers, drills, ibikoresho bitobora, nibindi, mu gukata ibyuma bikozwe mu cyuma, ibyuma bidafite feri, plastiki, imigozi ya shimi, grafiti, ikirahure, amabuye n'ibyuma bisanzwe, kandi ishobora no gukoreshwa mu gukata ibikoresho bigoranye gukoresha imashini nk'icyuma kidashyuha, icyuma kidashonga, icyuma cya manganese nyinshi, icyuma cy'ibikoresho, nibindi. Umuvuduko wo gukata ibikoresho bishya bya carbide ubu ukubye inshuro amagana ugereranije n'icyuma cya karubone.

Gukoresha karubide ikozwe muri sima

(1) Ibikoresho by'ibikoresho

Karubide ni igikoresho kinini cyane, gishobora gukoreshwa mu gukora ibikoresho byo guhindukira, imashini zisya, planers, imashini zitobora, nibindi. Muri byo, karubide ya tungsten-cobalt ikwiriye gukoreshwa mu gutunganya ibyuma bito n'ibitari feri mu buryo bw'igihe gito no gutunganya ibikoresho bitari ibyuma, nk'icyuma gishongeshejwe, umuringa ushongeshejwe, bakelite, nibindi; karubide ya tungsten-titanium-cobalt ikwiriye gukoreshwa mu gutunganya ibyuma bishongeshejwe mu gihe kirekire nk'icyuma. Gutunganya ibyuma bito. Mu bikoresho bisa, bifite kobalt nyinshi bikwiriye gukoreshwa mu gutunganya ibyuma bito, naho ibifite kobalt nke bikwiriye kurangiza. Karubide zikozwe muri sima zikoreshwa muri rusange zimara igihe kirekire cyane mu gutunganya ibyuma kurusha izindi karubide zikozwe muri sima ku bikoresho bigoye gukoresha nk'icyuma kidafunze.

(2) Ibikoresho by'ibumba

Karubide ikoreshwa cyane cyane mu gukora ibikoresho bikonje nk'ibikoresho bikonjesha, ibikoresho bikonjesha, ibikoresho bikonjesha byo gusohora ibikoresho, n'ibikoresho bikonjesha byo gutwikira ibikoresho.

Ibyuma bikonjesha bya karuboni birakenewe kugira ngo bigire imbaraga zikomeye, bikomere, binanire, binanuke kandi birambe neza mu gihe cy’imikorere idashira cyangwa ikomere cyane. Ubusanzwe hakoreshwa ubwoko bw’ibinyampeke bya kobalti biri hagati n’ibinini n’ibinini, nka YG15C.

Muri rusange, isano iri hagati yo kudashira no gukomera kwa karubide ikozwe muri sima iravuguruzanya: kwiyongera k'ubudashira bizatuma gukomera kugabanuka, kandi kwiyongera k'ubudashira bizatera kugabanuka k'ubudashira. Kubwibyo, mu guhitamo ingero z'imashini, ni ngombwa kuzuza ibisabwa byihariye mu mikoreshereze hakurikijwe ikintu gitunganywa n'imiterere y'akazi ko gutunganya.

Niba urwego rwatoranijwe rushobora kwangirika hakiri kare mu gihe cyo gukoresha, urwego rufite imbaraga nyinshi rugomba gutoranywa; niba urwego rwatoranijwe rushobora kwangirika hakiri kare mu gihe cyo gukoresha, urwego rufite imbaraga nyinshi kandi rudashira neza rugomba gutoranywa. . Ingano zikurikira: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Uhereye ibumoso ujya iburyo, imbaraga ziragabanuka, imbaraga ziragabanuka, kandi imbaraga zirazamuka; ahubwo, ibinyuranye n'ibyo ni ukuri.

(3) Ibikoresho byo gupima n'ibice bidashobora kwangirika

Karubide ikoreshwa mu gupima ibintu bidashira no mu bice by'ibikoresho bipima, ibyuma bipima neza, ibyuma biyobora n'imigozi y'ibyuma bisya bitagira hagati, hejuru y'ibyuma bifunga n'ibindi bice bidashira.

Ibikoresho byo gufunga ubusanzwe ni ibyuma byo mu itsinda ry'icyuma, akenshi ni cobalt na nikeli.

Mu gukora karubide ikozwe muri sima, ingano y'uduce tw'ifu y'ibikoresho byatoranijwe iri hagati ya mikoroni 1 na 2, kandi ubuziranenge buba buri hejuru cyane. Ibikoresho fatizo bishyirwa mu byiciro hakurikijwe ingano yagenwe y'ibikubiye mu bubiko, hanyuma alcool cyangwa ibindi bikoresho bishyirwa mu gusya bitose mu ruganda rutose kugira ngo bivange neza kandi bisya. Hindura uruvange. Hanyuma, uruvange rurashyirwa mu ngano, rugakanda, hanyuma rugashyuha kugeza ku bushyuhe bwegereye aho icyuma gishongesha (1300-1500 °C), igice gikomeye n'icyuma gishongesha bizakora ifu ya eutectic. Nyuma yo gukonjesha, ibice bikomeye bikwirakwizwa mu ruziga rugizwe n'icyuma gishongesha kandi bihuzwa cyane kugira ngo bikore ikintu gikomeye. Ubukana bwa karubide ikozwe muri sima buterwa n'ingano y'igice gikomeye n'ingano y'ingano, ni ukuvuga ko uko igice gikomeye kiba kinini kandi ingano ntoya zigakomera, ni ko ubukana buba bwinshi. Ubukana bwa karubide ikozwe muri sima bugenwa n'icyuma gishongesha. Uko icyuma gishongesha kiba kinini, niko imbaraga zo kuzunguruka ziba nyinshi.

Mu 1923, Schlerter wo mu Budage yongeyeho 10% kugeza kuri 20% bya cobalt muri tungsten carbide powder nk'igikoresho cyo gufunga, maze avumbura alloy nshya ya tungsten carbide na cobalt. Ubukana ni ubwa kabiri nyuma ya diyama. Carbide ya mbere ikozwe muri sima. Iyo ukata icyuma ukoresheje igikoresho gikozwe muri iyi alloy, inkombe ishaje vuba, ndetse n'inkombe ishaje izacika. Mu 1929, Schwarzkov muri Leta Zunze Ubumwe za Amerika yongeyeho ingano runaka ya tungsten carbide na titanium carbide compound carbides ku mvange y'umwimerere, byatumye igikoresho kirushaho gukora neza mu gukata icyuma. Iki ni ikindi gikorwa cyagezweho mu mateka y'iterambere rya sima ya carbide.

Karubide ikoze muri sima ifite imiterere myiza cyane nko gukomera cyane, kudashira, gukomera no gukomera, kudashira ubushyuhe no kudashira, cyane cyane gukomera kwayo no kudashira, ariko ntibihinduka nubwo haba hari ubushyuhe bwa dogere selisiyusi 500, iracyafite gukomera cyane kuri dogere selisiyusi 1000. Karubide ikoreshwa cyane nk'ibikoresho by'ibikoresho, nko guhindukiza ibikoresho, gukata ibyuma, planers, imashini zitobora, nibindi, mu gukata ibyuma bikozwe mu cyuma, ibyuma bidakoresha feri, plastiki, imigozi ya shimi, grafiti, ikirahure, amabuye n'ibyuma bisanzwe, kandi ishobora no gukoreshwa mu gukata ibikoresho bigoranye gukoresha imashini nk'icyuma kidashyuha, icyuma kidashonga, icyuma cya manganese nyinshi, icyuma cy'ibikoresho, nibindi. Umuvuduko wo gukata ibikoresho bishya bya karubide ubu ukubye inshuro amagana ugereranije n'icyuma cya karuboni.

Karubide ishobora kandi gukoreshwa mu gukora ibikoresho byo gucukura amabuye, ibikoresho byo gucukura amabuye, ibikoresho byo gucukura, ibikoresho byo gupima, ibice bidashobora kwangirika, ibikoresho byo gukuba ibyuma, imiyoboro ya silindiri, ibyuma bipima neza, imiyoboro, imashini zikora ibikoresho by'icyuma (nk'insinga zikora ibikoresho, imashini zikora ibikoresho bya bolt, imashini zikora ibikoresho bya nut, n'ibindi bikoresho bitandukanye byo gufunga, imikorere myiza ya karubide ikozwe muri sima yasimbuye buhoro buhoro imashini zikora ibikoresho bya mbere by'icyuma).

Nyuma, karubide ifunze na yo yasohotse. Mu 1969, Suwede yakoze neza igikoresho gifunze karubide ya titaniyumu. Ishingiro ry'igikoresho ni karubide ya tungsten-titanium-cobalt cyangwa karubide ya tungsten-cobalt. Ubunini bw'igipfundikizo cya karubide ya titaniyumu hejuru ni mikoroni nke gusa, ariko ugereranije n'ubwoko bumwe bw'ibikoresho bya alloy, igihe cyo gukora cyongerwaho inshuro 3, kandi umuvuduko wo gukata wongerwaho 25% kugeza kuri 50%. Mu myaka ya 1970, ibikoresho bya kane byakoreshejwe mu gukata ibikoresho bigoye gukoresha imashini byagaragaye.

Karubide ikozwe muri sima ikoreshwa gute?

Karubide ikozwe muri sima ni icyuma gikozwe mu byuma bikozwe mu byuma bikozwe mu byuma bifunga by'icyuma kimwe cyangwa byinshi birwanya ubukana bwacyo.

Mibihugu bitunganya umusaruro

Hari ibihugu birenga 50 ku isi bikora karubine ikozwe muri sima, umusaruro wose ukaba ungana na toni 27.000-28.000. Abakora cyane ni Leta Zunze Ubumwe za Amerika, Uburusiya, Suwede, Ubushinwa, Ubudage, Ubuyapani, Ubwongereza, Ubufaransa, nibindi. Isoko rya karubine ikozwe muri sima ku isi ryuzuyemo. , irushanwa ku isoko rirakomeye cyane. Inganda za karubine zikozwe muri sima mu Bushinwa zatangiye kugaragara mu mpera za 1950. Kuva mu myaka ya 1960 kugeza mu myaka ya 1970, inganda za karubine zikozwe muri sima mu Bushinwa zateye imbere vuba. Mu ntangiriro za 1990, ubushobozi bwose bw'umusaruro wa karubine ikozwe muri sima mu Bushinwa bwageze kuri toni 6000, kandi umusaruro wose wa karubine ikozwe muri sima wageze kuri toni 5000, uwa kabiri nyuma ya Mu Burusiya na Leta Zunze Ubumwe za Amerika, uza ku mwanya wa gatatu ku isi.

Igikato cy'isuku

①Tungsten na cobalt sima carbide

Ibice by'ingenzi ni tungsten carbide (WC) na binder cobalt (Co).

Ingano yayo igizwe na "YG" ("ikomeye na cobalt" mu gishinwa cya Pinyin) n'ijanisha ry'ikigereranyo cy'ingano ya cobalt.

Urugero, YG8 bivuze impuzandengo ya WCo=8%, naho igisigaye ni tungsten-cobalt carbide ya tungsten carbide.

Imihoro ya TIC

②Tungsten-titanium-cobalt carbide

Ibice by'ingenzi ni tungsten carbide, titanium carbide (TiC) na cobalt.

Ingano yayo igizwe na "YT" ("inyuguti ebyiri zikomeye, titaniyumu" mu gice cy'ibanze cya Pinyin cy'Igishinwa) n'ikigereranyo cy'ingano ya titaniyumu karubide.

Urugero, YT15 bivuze WTi isanzwe = 15%, naho ibisigaye ni tungsten carbide na tungsten-titanium-cobalt carbide ifite kobalti.

Igikoresho cya Tungsten Titanium Tantalum

③Tungsten-titanium-tantalum (niobium) karubide ikoze muri sima

Ibice by'ingenzi ni tungsten carbide, titanium carbide, tantalum carbide (cyangwa niobium carbide) na cobalt. Ubwo bwoko bwa sima buzwi kandi bwitwa general cemented carbide cyangwa universal cemented carbide.

Ingano yayo igizwe na "YW" (inyuguti y'igishinwa ya "hard" na "wan") hamwe n'inomero y'uruhererekane, nka YW1.

Ibiranga imikorere

Ibyuma bya Karubide byasutsweho

Ubukomere bwinshi (86~93HRA, bingana na 69~81HRC);

Ubushyuhe bwiza (kugeza kuri 900 ~1000 ℃, komeza kuri 60HRC);

Ubudahangarwa bwiza bwo kwangirika.

Ibikoresho byo gukata karubine byihuta inshuro 4 kugeza kuri 7 kurusha icyuma cyihuta cyane, kandi igihe cyo gukoresha ibikoresho kiri hejuru y’inshuro 5 kugeza kuri 80. Mu gukora ibikoresho byo gushushanya no gupima, igihe cyo gukoresha ibikoresho kiri hejuru y’inshuro 20 kugeza kuri 150 kurusha icy’icyuma cyo gushushanya. Bishobora gukata ibikoresho bikomeye bigera kuri 50HRC.

Ariko, karubide ikozwe muri sima iracikagurika kandi ntishobora gukoreshwa mu mashini, kandi biragoye gukora ibikoresho by’ingenzi bifite imiterere igoye. Kubwibyo, akenshi hakorwa ibyuma by’imiterere itandukanye, bigashyirwa ku mubiri w’igikoresho cyangwa ku mubiri w’ibumba hakoreshejwe gusudira, gufatanya, gufunganya mu buryo bw’ikoranabuhanga, nibindi.

Urubaho rufite ishusho yihariye

Gutunganya

Gutunganya karubide ikoresheje sima ni ugushyira ifu mu gikoresho cyo gukaraba, hanyuma ukinjira mu itanura kugira ngo ushyushye kugeza ku bushyuhe runaka (ubushyuhe bwo gukaraba), ukayigumana igihe runaka (igihe runaka), hanyuma ukayikonjesha kugira ngo ubone ibikoresho bya karubide ikoresheje sima bifite imiterere ikenewe.

Uburyo bwo gutwika karubine ikoresheje sima bushobora kugabanywamo ibice bine by'ibanze:

1: Mu cyiciro cyo gukuraho ikintu cyakozwe mbere yo kugikuraho, umubiri wakuwemo uhinduka ku buryo bukurikira:

Gukuraho ikintu gikoreshwa mu gushushanya, hamwe n’ubushyuhe bwiyongera mu ntangiriro zo gushushanya, ikintu gikoreshwa mu gushushanya kirabora cyangwa kigahinduka umwuka, maze umubiri wakoreshejwe mu gushushanya ntubarwemo. Ubwoko, ingano n’uburyo bwo gushushanya biratandukanye.

Oxyde ziri ku buso bw'ifu ziragabanuka. Iyo ubushyuhe butangiye gushonga, hydrogen ishobora kugabanya oxyde za cobalt na tungsten. Iyo igikoresho cyo kurema gikuwe mu cyuma gishyushye kikajugunywa, imikorere ya karuboni na ogisijeni iba idakomeye. Imiterere y'uduce tw'ifu iragabanuka buhoro buhoro, ifu y'icyuma ihuza itangira kugaruka no kongera gushya, gukwirakwira kw'ubuso bitangira kubaho, kandi imbaraga zo gufunga briquet zirushaho kwiyongera.

2: Icyiciro cyo gutwika igice gikomeye (ubushyuhe bwa 800℃–eutectic)

Ku bushyuhe mbere yuko habaho icyiciro cy'amazi, uretse gukomeza inzira y'icyiciro cyabanje, uburyo bwo gukora no gukwirakwiza ibintu mu gice cy'ingenzi birakongerwa, urujya n'uruza rwa plastiki rurarushaho kwiyongera, kandi umubiri urimo gushwanyagurika uragabanuka cyane.

3: Icyiciro cyo gushonga mu gice cy'amazi (ubushyuhe bwa eutectic - ubushyuhe bwo gushonga)

Iyo igice cy'amazi kigaragara mu mubiri warimo gushwanyagurika, gushwanyagurika kurangira vuba, hagakurikiraho impinduka za kristalografiya kugira ngo habeho imiterere n'imiterere y'ibanze ya alloy.

4: Icyiciro cyo gukonjesha (ubushyuhe bwo gushyuha - ubushyuhe bw'icyumba)

Muri iki cyiciro, imiterere n'imiterere y'icyiciro bya alloy bigira impinduka zimwe na zimwe bitewe n'imiterere itandukanye y'ubukonje. Iki kintu gishobora gukoreshwa mu gushyushya karubide ikozwe muri sima kugira ngo inoze imiterere yayo ifatika n'iy'ikoranabuhanga.

Igihe cyo kohereza: Mata-11-2022